UV treatment of corrosive liquids including sea water

UV disinfection is well regarded worldwide for the effective chemical free disinfection of water. Highly corrosive environments such as seawater and industrial waters containing organic solvents, acids and alkalis can now be cost effectively treated with UV thanks to the polypropylene range of UV disinfection systems manufactured by UltraAqua. Polypropylene options are available in the closed reactor (barrel style), open channel and reservoir suitable systems.

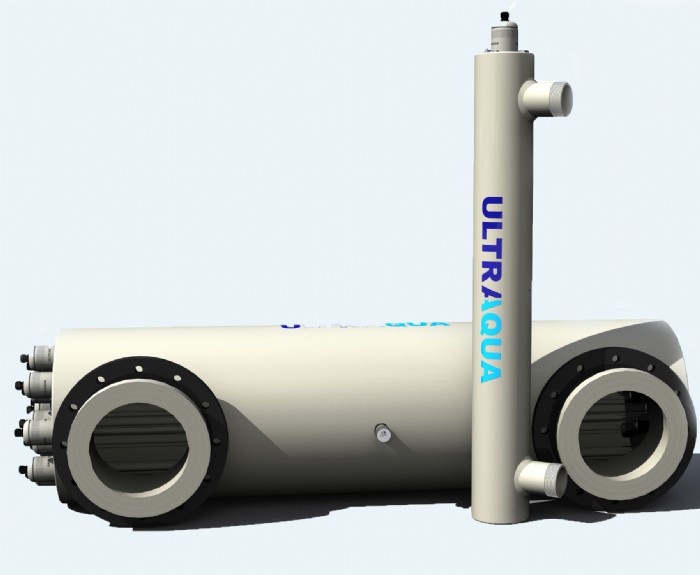

PolyPropylene Closed UV System

UltraAqua's polypropylene (PP) UV disinfection systems are completely corrosion resistant and ideal not only for sea water and aquaculture, they also have a very high chemical resistance. They are resistant to organic solvent as well as acids and alkalis. Polypropylene has a design stress of 1,000 psi at 22.7 ºC and is excellent for laboratory and industrial drainage pipes where mixtures of acids, bases and solvents are involved.

UltraAqua Corrosion Resistant UV Disinfection System (Closed Reactor)

ULTRAAQUA’s polypropylene (PP) closed reactor series offers very high quality at a reasonable price. They are extremely versatile due to their corrosion-resistant construction and a flow range from 5 to 1000 m3/h. As a result of attractive price/performance ratio and excellent long term experiences many customers select PP reactor based systems also for fluids that are non-corrosive. The major benefits are:

- Rigid, corrosion-resistant construction from DIN 8061/62 industrial grade polypropylene for very harsh environments

- Simple installation, simple operation and maintenance

- Available with standard or advanced control cabinets

- Optional UV monitoring with digital UV Önorm approved sensors

- Available with DIN or ANSI flanges

- No tools needed for scheduled maintenance

Considerations When Choosing a Polypropylene or Stainless Steel UV System

UltraAqua UV systems based on polypropylene (PP) material are completely corrosion resistant. They can be used in all water salinities at temperatures up 80 ºC. However, please note that the UltraAqua range of stainless steel UV reactors are made of high grade AISI316L steel which has been passivated and electropolished internally as well as externally. Corrosion resistance is very high for these as well. As a rule of thumb choose polypropylene (PP) reactors if sea water temperatures exceed 25 ºC.

Customisation

UltraAqua also delivers UV systems with customised connection sizes and/ or orientation of connections (L, Z or angled configuration). It is also possible to combine control panels for installations where multiple UV reactors operate simultaneously.

Ultraaqua is a well-established manufacturer of high-quality UV system. Ultraaqua’s design team employs dedicated engineers with research careers of the highest academic level and many years of experience in design and operation of water treatment facilities. With a “keep it simple” design philosophy the focus is to reduce complexity, increase reliability and produce robust UV disinfection systems for high reliability in harsh environments.

Ultraaqua is a well-established manufacturer of high-quality UV system. Ultraaqua’s design team employs dedicated engineers with research careers of the highest academic level and many years of experience in design and operation of water treatment facilities. With a “keep it simple” design philosophy the focus is to reduce complexity, increase reliability and produce robust UV disinfection systems for high reliability in harsh environments.