Bioassayed UV disinfection for pre-treatment process water

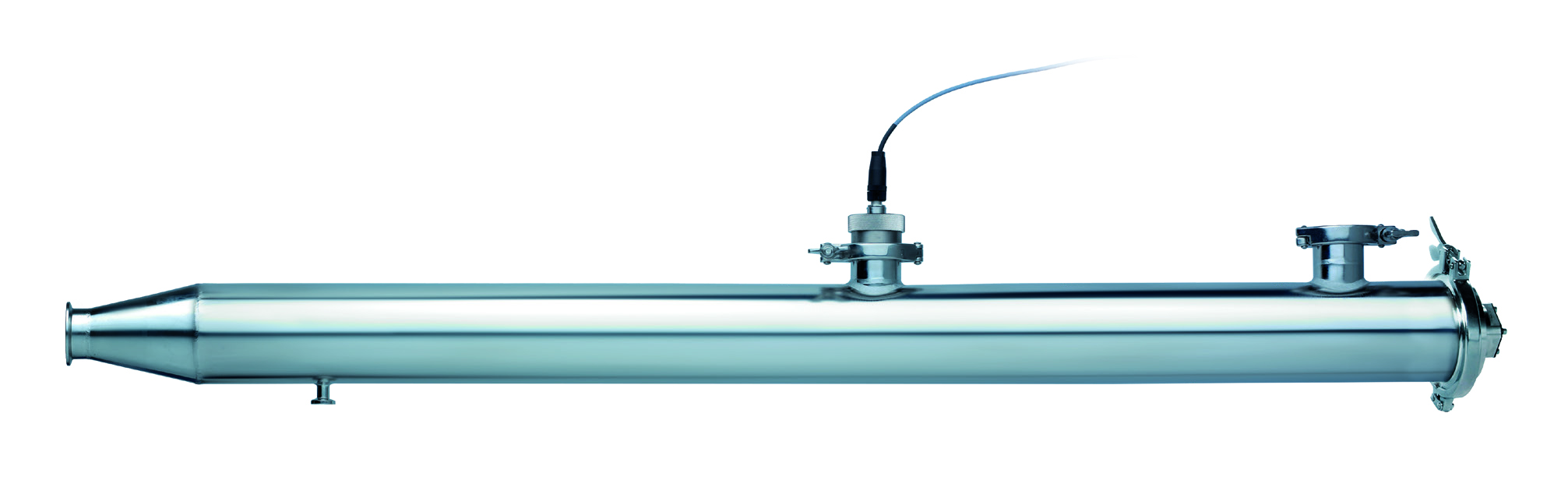

Our PharmaLine PQ AF systems are aimed specifically at providing third party bioassayed UV disinfection for Purified Water Generation System Pre-treatment where sanitary design is not critical. By using a third party bioassayed UV system you can be certain that the UV dose being produced will disinfect the water, eliminate objectionable organisms, reduce the bioburden, protect against bio-fouling, lead to fewer CIP / SIP cycles and lower operating costs.

Each system comes with a certified dry UV sensor and UVGuard™ sensor window allowing easy checking of UV performance while the system continues to operate. The UV sensor measures the germicidal output of the UV system and a UV dose read out makes it easy to monitor and log performance.

The systems all use low pressure amalgam lamps providing an energy efficient germicidal wavelength, long lamp life to reduce operating costs and can be easily installed to existing processes.

The control system also has the ability to take flow and transmittance meter inputs and calculate the UV dose based on real time operating conditions.

Bioassayed UV disinfection for Purified Water and distribution (Hygenic Design-H)

Our PharmaLine PQ AF H systems are designed for hygiene based on cGMP principles and aimed specifically at providing third party bioassayed UV disinfection in Pharmaceutical Purified

Water Generation and distribution loop systems where sanitary design is critical. By using a third party bioassayed UV system you can be certain that the UV dose being produced will disinfect the water, eliminate objectionable organisms, reduce the bio-burden, protect against bio-fouling, lead to fewer CIP / SIP cycles and lower operating costs.

Each system comes with a certified dry UV sensor and UVGuard™ sensor window allowing easy checking of UV performance while the system continues to operate. The UV sensor measures the germicidal output of the UV system and an RED dose read out makes it easy to monitor and log performance.

The systems all use low pressure amalgam lamps providing an energy efficient germicidal wavelength, long lamp life to reduce operating costs and can be easily installed to existing processes.

The control system also has the ability to take flow and transmittance meter inputs and calculate the UV dose based on real time operating conditions.